FAQs of Working with Jockimo Architectural Glass Products

- Details

Is Jockimo the Right Glass Manufacturer for You?

You’ve done ome preliminary research. You’ve seen samples and portfolios. You’ve narrowed your list of potential glass manufacturers down to a handful. Jockimo Architectural Glass Products is on that list. Now you need to determine if we’re the best fit for you and your glass project. Here are ten frequently asked questions about working with us to help you make that decision.

10 Common Questions (and Answers) about Working with Jockimo

-

How Do You Ensure the Safety of Your Glass Flooring?

Safety must be your biggest concern when it comes to glass flooring. Ask any potential glass manufacturer about their safety standards. If you’re not fully happy with their answer, move on.

With every glass floor project, we go through rigorous testing, verification, and code compliance.

-

Antislip Surface

All glass floors should use an antislip surface. This should be properly tested and comply with all worldwide anti-slip standards. This includes the United States, the United Kingdom, the European Union, and Australia.

Don’t hesitate to request documentation to ensure the manufacturer is providing valid, sufficient, and authentic anti-slip glass.

-

Failure Redundancy

For a glass floor or glass stair treads to be compliant with the latest ASTM codes, a minimum of three pieces of glass must make up each glass panel.

This failure redundancy ensures the flooring panel will stay structurally sound, even if one layer manages to break.

Any glass flooring should be fully compliant with all ASTM codes and standards. Again, don’t hesitate to ask for this documentation through their engineering reports.

-

Glass Thickness

Glass thickness is determined by ASTM standards, international building codes, and the specific engineering calculations for a given project. Every glass floor we create has the input of an engineer with specific glass experience to ensure the safety of the end product.

Want to know more? Read Are Glass Floors Safe?

-

What Sizes of Glass Panels Are Available?

Every glass project we create is custom. The size of the glass panels is only limited by safety considerations, weight, and maximum spans.

The largest single glass flooring panel Jockimo created was 40 square feet and approximately 700 pounds.

Keep in mind that extremely large glass panels often require extra support to accommodate the weight. This is possible, but it does increase budget expectations.

When designing your specific project, we work closely with the project engineer to determine maximum potential weight and size of each panel.

-

Can You Make Custom Shapes with the Glass Panels?

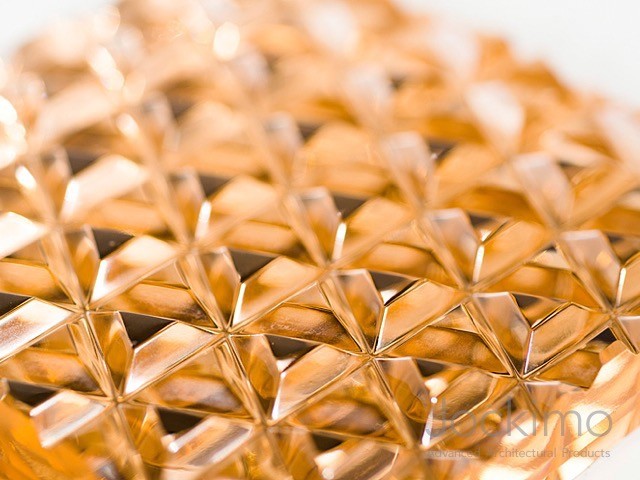

Yes. Jockimo specializes in custom glass projects. This includes panel:

- Size

- Shape

- Color

- Texture

- Pattern

- Level of transparency

We love designing and creating one-of-a-kind projects for our customers, and we always do so with the input and expertise of a qualified project engineer.

-

How Thick Will My Glass Panels Be?

Most standard flooring projects are made up of three 3/8” lites. This brings the total thickness to about 1 ¼” . Again, though, every project is fully custom.

As long as our project engineers fully sanction the design for safety, individual glass flooring panels can be thicker than that.

-

Do You Provide Framing or Installation for My Glass Flooring Panels?

Jockimo is a custom glass manufacturer. Our specialty is in the design and production of architectural glass products. We do not personally install these glass projects, and we do not design or provide the support system, frame, or hardware.

That being said, we’ve been active in the glass industry for decades. Especially throughout most of North America, we have many recommendations for glaziers and metal fabricators.

-

Do You Work with an Engineer to Design Your Glass Floors?

Yes. Your project will come with wet stamped complete engineering calculations.

Because safety is such an important consideration with glass flooring, every Jockimo project has the design contributions and safety calculations of an engineer with specific glass experience.

-

What Are Your Lead Times for Architectural Glass Products?

Our glass flooring typically has a lead time of six to eight weeks. This starts from the date of order confirmation.

If you need your order rushed, contact us to discuss. We might be able to accommodate.

-

How Do You Ship Your Architectural Glass Products?

Every architectural glass product we create is packaged in a custom wooden crate. These are produced to project specifications for each individual order. Be aware: there can be additional costs associated with crating.

Common carriers will typically handle shipments, but alternative shipping methods are available too. (If you have something specific in mind, we can discuss.)

-

What Are the Payment Terms for Your Glass Products?

For any glass project, we require a 50% deposit with the order. Prior to shipping, we invoice for any remaining balance.

-

How Do I Take the Next Steps and Work with Jockimo?

If you’re interested in working with Jockimo, please send us:

- Any plans you already have, including quantities and sizes of glass panels.

- Details about structural support systems (for flooring specifically).

- Panel sizes and type of Jockimo glass you’re interested in using.

All PDFs and information can be emailed to This email address is being protected from spambots. You need JavaScript enabled to view it..

If you’re unsure or still in the early design stages, no worries. Contact us, and we can work together to get your project off the ground.